- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

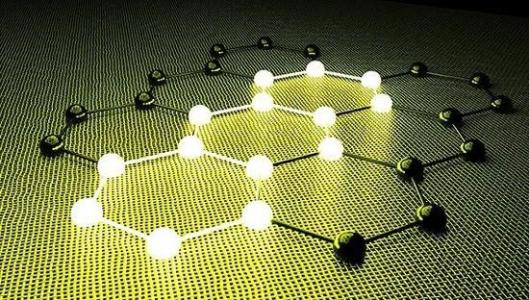

What is the application field of graphite?

US President recently decided to invoke a Cold War-era defense law to encourage domestic production of minerals needed to make batteries for electric cars.

This order, issued under the Defense Production Act (DPA), is expected to help miners secure government funding for feasibility studies for new projects to refine lithium, nickel, and other metals for electric vehicles, or to increase productivity at existing facilities.

The funds will not be used to dig new mines or buy minerals for government stocks, and the DPA does not allow the mining industry to evade regulatory or licensing standards. It is unclear how much money could be allocated.

Talon Metals Corp said this decision signaled the US would support responsible domestic mining, processing, and recycling of battery materials, and see it as a matter of national importance. The company has a supply agreement with Tesla to supply materials from a Minnesota nickel mine they are developing.

This move could cause volatility in the prices of metals and other commodities like the Graphite.

Graphite has many excellent properties, so it is widely used in metallurgy, machinery, electrical, chemical, textile, national defense, and other industrial sectors. The application fields of natural graphite and artificial graphite both overlap and differ from each other.

In the metallurgical industry, natural flake graphite can be used to produce refractory materials such as magnesia-carbon bricks and aluminum-carbon bricks because of its good oxidation resistance.

Artificial graphite can be used as steelmaking electrodes, while electrodes made of natural graphite are difficult to use in steelmaking electric furnaces with harsh operating conditions.

In the machinery industry, graphite materials are usually used as wear-resistant and lubricating materials. Natural flake graphite has good lubricity and is often used as an additive to lubricating oils.

The equipment for conveying corrosive media widely uses piston rings, sealing rings, and bearings made of artificial graphite, and need not add lubricating oil when working.

Natural graphite and polymer resin composite materials can also be used in the above fields, but the wear resistance is not as good as that of artificial graphite.

Artificial graphite has the characteristics of corrosion resistance, good thermal conductivity, and low permeability. It is widely used in the chemical industry to make heat exchangers, reaction tanks, absorption towers, filters, and other equipment.

Natural graphite and polymer resin composite materials can also be used in the above fields, but the thermal conductivity and corrosion resistance are not as good as those of artificial graphite.

Conclusion

To sum up, the development of artificial graphite products with natural graphite as raw material is one of the important ways to expand the application field of natural graphite.

Natural graphite as an auxiliary raw material has long been used in the production of some artificial graphite, but there are still many problems to be solved in the development of artificial graphite products with natural graphite as the main raw material.

Fully understanding and utilizing the structure and properties of natural graphite, and adopting suitable process routes and methods to produce artificial graphite products with special structures, properties, and uses should be the best way to achieve this goal.

High quality graphite manufacturer

Luoyang Moon & Star New Energy Technology Co., LTD, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.

If you are looking for graphite or lithium battery anode material, click on the needed products and send us an inquiry:sales@graphite-corp.com

Since February, gold has enjoyed a smooth upward run on the back of surging US inflation and the brewing of war. While expectations of rate rises have also risen in tandem over this period, gold had been largely pre-priced and the underlying driver of tightening expectations had come from inflation continuing to rise to record highs. The risk aversion caused by the continued tension in the war also provided an important short-term support for gold. This will have a certain impact on the price of the Graphite and the market of the Graphite.

Inquiry us