Durable and versatile chemical fibers for textiles, composites, and more. Excellent quality, competitive rates, and reliable delivery.

** From Goo to Glamour: Bush Trip of Carbon Fiber **.

(how is carbon fiber made)

Carbon fiber is everywhere nowadays. You see it in sports cars, aircrafts, bikes, also elegant phone cases. Yet how does this light-weight, super-strong material go from a sticky mess to the sleek things of desires? Allow’s simplify.

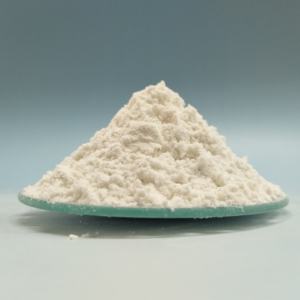

It all begins with something called a “precursor.” This is the raw material that obtains become carbon fiber. A lot of the moment, the precursor is a type of plastic called polyacrylonitrile, or PAN for short. Think of frying pan as the dough before it ends up being bread. Other times, manufacturers use pitch– a gooey result of oil or coal. However PAN is the celebrity right here because it makes the toughest carbon fiber.

Step one is rotating. PAN obtains developed into fibers, sort of like exactly how cotton candy is rotated from sugar. The frying pan is liquified into a fluid, then pressed via small nozzles to create slim hairs. These strands are cleaned and stretched to line up the molecules inside. This makes the fibers stronger. Picture drawing an item of eating periodontal until it’s thin and tight– similar concept.

Following comes stablizing. The fibers obtain heated in a stove, but not as well warm. The temperature level begins around 200– 300 ° C, and the fibers are exposed to oxygen. This action is sluggish, taking hours. Oxygen alters the chemical structure of the PAN, making it secure enough to deal with greater warmth later. If you miss this, the fibers would certainly simply melt or shed. It resembles teaching the fibers to make it through a workout prior to tossing them into a marathon.

Currently, the genuine magic occurs: carbonization. The supported fibers enter into another oven, this moment without any oxygen. Temperatures skyrocket– up to 3,000 ° C. At this point, everything that isn’t carbon obtains burned off. What remains is a fiber made nearly entirely of carbon atoms. These atoms form securely bonded crystals, lined up along the fiber’s length. This crystal structure is why carbon fiber is so solid. Image billions of little blocks piled flawlessly– no gaps, no weak points.

Yet wait, carbon fibers alone are breakable. They resemble raw spaghetti– stiff however easy to break. To make them valuable, they’re bundled into strings and woven right into fabrics or sheets. After that comes the glue: epoxy material. The carbon fiber textile is layered into mold and mildews, taken in resin, and cured (solidified) under warm or pressure. This produces a composite material– carbon fibers provide strength, while the resin waits together. It resembles concrete with rebar, but means lighter.

Shades are one more technique. Raw carbon fiber is black due to the fact that it’s pure carbon. Yet you have actually most likely seen carbon fiber with great patterns or colors. That’s done by adding dyes to the material or using colored fabrics during weaving. The final product obtains sanded, brightened, or coated for that shiny finish.

Making carbon fiber isn’t fast or affordable. The high warmth, exact controls, and multiple actions add up. However the outcome is worth it. A product five times stronger than steel, two times as rigid, and method lighter. Not surprising that it’s enjoyed by designers and designers alike.

(how is carbon fiber made)

So next time you find carbon fiber in an automobile hood or a tennis noise, remember its trip. From sticky PAN soup to blazing ovens to modern resin baths– it’s a makeover story science would take pride in.