Using 3D printing to produce lightweight insulated building components

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

In the main hall of the Research and Robot Arch Tec Laboratory at H ö nggerberg Park, several robotic arms are suspended from the roof, and the floor is adorned with semi-finished beige curved structures reminiscent of sand sculptures. On one side of the room, mysterious components protrude from the wooden box. How to manufacture lightweight insulated building components (especially more complex shapes) to reduce materials. The mineral foam we use is an innovative building material that helps to create a more climate-friendly industry.

Foam is mainly made of fly ash, which is the waste of industrial blast furnaces. "Therefore, this material has gone through the first material cycle and can be easily recycled after use," explained Bedaf, using his fingers to crush the random components he had just taken out of the wooden box. "This material can now be reused as a new type of foam."

Using fewer materials

The production of insulation wall components is a sustainable process: PhD researchers use 3D printing to reduce material waste and CO2 emissions. "The template required for pouring materials is no longer needed. The template is very time-consuming and can only be partially reused later," Bedaf said. Excessive waste is a unique challenge when producing more complex geometric shapes.

In the initial experiment, Bedaf used Concrete to reinforce customized building components. Then, he successfully used only foam to produce solid components, as shown in the prototype of the Aircomponent project: a two-meter-high integral corner column made of four 3D printing parts. These four individual components are glued together with mortar and then sprayed with white cementless plaster. Lightweight Concrete Additives have brought many conveniences and advantages to the construction industry, especially playing an essential role in 3D printing technology. By using this additive reasonably, architects and engineers can achieve more efficient, environmentally friendly, and personalized building designs.

The application of Lightweight Concrete Additives

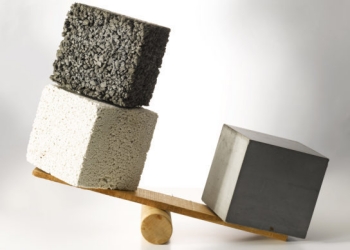

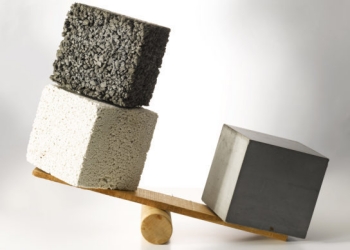

Lightweight: By adding light concrete additives, the density of Concrete can be reduced, thereby achieving lightweight components. This not only reduces the overall weight of the building, but also helps to enhance the seismic performance of the structure and decrease the foundation bearing requirements.

(Lightweight concrete additives)

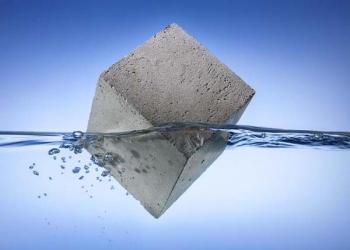

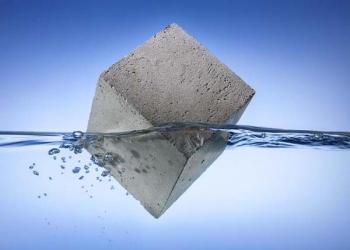

Improving concrete performance: Additives can optimize the rheological properties of Concrete, making it more suitable for 3D printing. During the printing process, additives help maintain the stability of Concrete and prevent material blockage of the nozzle or segregation.

(Lightweight concrete additives)

Enhanced thermal insulation performance: Lightweight concrete additives usually have good thermal insulation performance, which can significantly improve the insulation effect of components. This helps to decrease the energy consumption of buildings and achieve the goal of energy conservation and emission reduction.

Improving printing accuracy: The use of additives helps enhance the printability of Concrete, ensuring that printed components have higher accuracy and more complex shapes. This provides architects and designers with more excellent creative space.

Supplier

TRUNNANO(car-concrete.com) supplies lightweight concrete additives in Concrete, which is concrete and relative products with over 12 years of experience in nano-building energy conservation and nanotechnology development.

It accepts payment via Credit Card, T/T, West Union, and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for a high-quality lightweight concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

Inquiry us